Brett Roosendaal

Technical Executive Animal Feed

RCL FOODS, Animal Feed

March 2015

Introduction

Soyabean meal is the most important source of dietary protein for poultry in South Africa and much of the world. The increased use of vegetable protein meals in animal feeds has been brought about through consumer pressure for more sustainable and welfare oriented animal protein production. The increased use of vegetable protein sources has highlighted the importance of protein quality and the methods used to control quality have increased proportionately. This is particularly evident in the case of chicks where protein quality is a major factor in early growth and performance, but is equally important in the feeding of older birds where feed cost and conversion are the determining economic parameters. Feed manufactures use the quality criteria and consistency of those criteria as the primary reason for selected soyabean meal of a specific supplier.

Soyabean is an excellent source of protein as alluded to above, however, this potential can only be achieved after heat treatment. Heat labile anti-nutritional factors present in soyabeans, including protetease inhibitors, lectins, goitrogens and anti-vitamines can cause inhibition of growth, decreased feed efficiency, goitrogenic responses, pancreatic hypertrophy, hypoglycemia and liver damage in poultry depending on age, sex, health status and plane of nutrition. Raw soyabeans are known to contain two separate protease inhibitors: 1) proteins with a molecular weight of about 20,000 Da and a specificity directed primarly against trypsin, known as the Kunitz trypsin inhibitor and 2) those that have a molecular weight between 6,000 to 12,000 Da and are capable of inhibiting chymotrypsin as well as trypsin at independent sites, referred to as the Bowman-Birk trypsin inhibitor. The second of the major anti-nutritional factors are lectins. Lectins are glycoproteins with the ability to bind carbohydrate-containing molecules on the epithelial cells of the intestinal mucosa, with toxcicity determined by the extent of binding.

Differentiation

Different sources of soyabean meal products are marketed to and used in the animal feed industry. Chemical composition of soyabean meals of different origins are given in Table 1 (Mateos et al., 2011, 2012).

Table 1. Chemical composition of Soyabean meal from different origins

| n | DM | CP | CF | NDF | EE | SUC | STA | |

| Argentina | 136 | 88.5 | 45.4c | 4.8b | 9.2b | 1.7ab | 6.7b | 4.9b |

| Brazil | 131 | 88.6 | 46.6b | 5.5a | 10.6a | 1.8a | 5.7c | 4.6c |

| USA | 164 | 88.6 | 47.3a | 3.8c | 7.8c | 1.6b | 7.2a | 5.7a |

| SEM | 0.08 | 0.12 | 0.08 | 0.13 | 0.04 | 0.08 | 0.04 | |

| P | NS | *** | *** | *** | ** | *** | *** |

n – no. of samples, DM – dry matter, CP – crude protein, CF – crude fibre, NDF – neutral detergent fibre, EE – ether extract, SUC – sucrose, STA – stachyose, RAF – raffinose

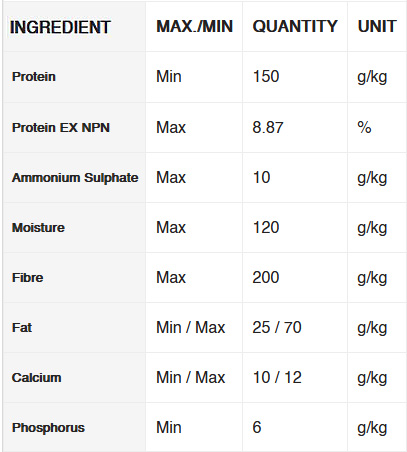

They are often completed with additional quality recommendations as indicated in Table 2.

Table 2. Recommended Quality measurements for soyabean meal

| Ash | less than 7.5% |

| Acid insoluble ash (silica) | less than 1% |

| Protein solubility index (0.2% KOH) | 75 – 85% |

| Protein dispersibility index | 15 – 40% |

| Urease activity | 0.00 – 0.05 pH unit rise |

| Trypsin inhibitor activity | less than 3 mg/g of meal |

| Bulk density | 57 – 64 g/100 ml |

| Screen analysis | 95% through a #10 mesh |

| 40 – 50% through a #20 mesh | |

| 6% maximum through a #80 mesh | |

| Colour | Uniform particle colours of light tan to light brown |

| Taste | bland |

| Contaminants | free from urea |

| free from melamine | |

| free of ammonia | |

| free from heavy metals | |

| free from Salmonella | |

| free from mycotoxins and mould |

Specifications such as these may vary among organizations and regions and although they provide a solid basis for commercial transactions, they are inadequate and of limited value when formulating diets.

Nutritional Aspects

Soyabean meal inclusion into poultry diets is determined largely by the nutrient specification of the diet to be formulated as well as the price. Other considerations that impact the inclusion of soyabean meal are the use of alternative proteinacious ingredients, animal performance levels sought and level of technological treatment (processing).

Soyabean meal is used as a protein source and therefore the most important criteria for its use are the level of digestible amino acids. Table 3 gives an indication of nutritional composition for poultry of soyabean meals (Mateos et al., 2011).

Table 3. Amino Acid Composition (% of protein) of Soyabean meals per origin

| ARG | BRA | USA | SEM | P | |

| n | 112 | 119 | 161 | ||

| Lysine | 6.09b | 6.06c | 6.16a | 0.005 | *** |

| Methionine | 1.36a | 1.33b | 1.36a | 0.002 | *** |

| Cysteine | 1.51a | 1.48b | 1.50a | 0.004 | *** |

| Treonine | 3.93a | 3.88b | 3.91a | 0.003 | *** |

| Tryptophan | 1.37a | 1.34c | 1.36b | 0.001 | *** |

The variation in amino acids as shown in Table 3 are closely related to fibre levels and to a number of anti-nutritional components. While fibre may account for the dilution effect between the two meals, differences in heat treatment still present one of the major sources of variation within types of soyabean meals.

Quality Variation and Control Methods

Variation in protein quality among samples of soyabean meal can occur due to either insufficient heating (under processing) or excessive heating (over processing). The following test methodologies are used to assess the quality of soyabean meal.

Urease: The presence of active trypsin can be indirectly determined by measuring the activity of urease enzyme present in soya. Both trypsin inhibitor and urease proteins are denatured and deactivated during heating. Urease, unlike trypsin inhibitors, is easy to measure, and because of it, it is used as a marker of trypsin inhibitor activity. Although the urease test is routinely done and often used in contract specifications, the results do not correlate well with animal performance.

KOH Protein Solubility: Protein solubility in a 0.2% KOH has been shown to be a good indicator of in vivo protein quality for over processed soyabean meal (Araba and Dale, 1990a; Parsons et al., 1991). The KOH solubility assay was also reported to be useful for detecting under processing of soyabean meal (Araba and Dale, 1990b); however, Anderson-Hafermann et al. (1992) later concluded that this assay was not very accurate for assessing under processing of soyabean meal. KOH results indicate that samples with high values are most digestible as long as urease activity is below the upper recommended limit.

Protein Dispersibility Index: The PDI assay has been used for at least 25 years in the food industry. Recent investigators have examined the value of PDI to predict growth of chicks fed various samples of soyabean meal. Results suggest that PDI is useful to further distinguish the quality of soyabean meal that is otherwise considered to be of good quality based on the urease and KOH measurements. Soyabean meal with a PDI between 45 and 50% and urease of 0.3 pH unit change or below indicate extremely high quality, adequately heat processed but not over toasted meal (Batal et al., 2000).

The measurement of the Trypsin Inhibitor Activity (TIA)appears not be that common, however, data from the literature indicates that activity levels of between 30 and 40 mg/g of soyabean meal indicates raw meal and levels lower than 5 mg/g as being acceptable for young animals (Clarke and Wiseman, 2001). The use of this quality control method for soyabean meal routinely is probably related to the complexity of the analysis as well as the time required.

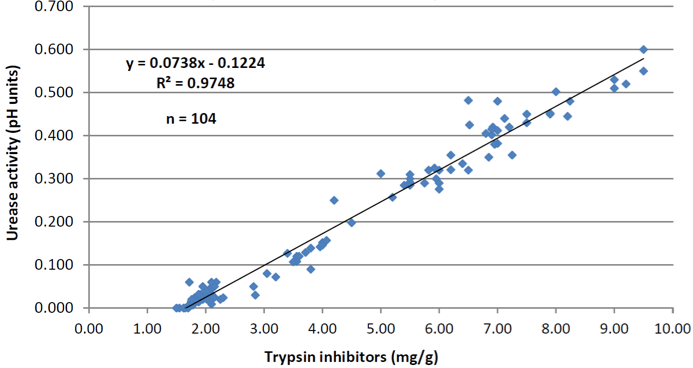

More recent data from 2005 (Ruiz and Belalcazar, 2005; Ruiz et al., 2008; Ruiz, 2012) indicated that excess intake of trypsin inhibitors in feed fed to broilers led to rapid feed passage. The authors further developed a regression equation which can assist with interpretation and is indicated in Figure 1.

Figure 1. Trypsin inhibitors versus Urease activity

Serrano et al., (2012) and Serrano et al., (2013) found no differences in broiler growth performance on 4 different soyabean meals tested, however, TIA levels were below 2.7 mg/g. Mateos et al. (2013) and Frikha et al. (2012) compared soyabean meals from 3 different origins, see Table 4.

Table 4. Protein Quality of soyabean meals according to origin

| n | Urea | TIA | KOH | PDI | |

| ARG | 118 | 0.02b | 2.5b | 82.2c | 16.7b |

| BRA | 125 | 0.03a | 2.6b | 82.9b | 15.4a |

| USA | 164 | 0.02ab | 3.1a | 86.8a | 19.7a |

| P | ** | *** | *** | *** |

Urease activity is very low for all samples, independent of country of origin. Using the most recent data available and extrapolating the results from these trials, it appears appropriate to re-access the ranges for the quality criteria. A summary of quality control tests with limits is provided in Table 5.

Table 5. Summary of Quality Control Tests for heat treated Soyabean Meal

| Test | Principal | Duration | Skill Level | Accuracy | Measurement | Recommended Values |

| Urease Index | Heat denatures urease and thus anti-nutritional components, mainly indicator of under heating | 20 min | Low | Average | pH increase due to ammonia release | 0.00 – 0.05 |

| 0.2% KOH solubility | Over heating reduces N solubility in 0.2% KOH quantification of over heating | 20 min | Low/Ave | Average | Protein solubilised | 75 – 85% |

| PDI | Heating reduces N solubilisation in water, quantification of underheating | 10 min | Low/Ave | Good | Protein solubilised | 15 – 45% |

| TIA (Trypsin Inhibitor Activity | Direct measurement of trypsin inhibitor, also indicator of all anti-nutritional components | >24hours | High | Good | Presence of trypsin inhibitors | < 3 mg/g |

| Dye-Binding (cresol red – Soy-Check)) | Measures lysine (free epsilon amino group), reduced by overheating | <10 min | Low | Low | Dye binding related to protein solubility | 5 – 6.5 mg/g |

Conclusion

Commercial specifications of soyabean products provide limited information on soyabean meal for diet formulation, detailed nutritional specifications are required. Table values are inadequate since bioavailability will vary with origin, variety and production conditions. Within a specific soyabean meal product, major variation in digestibility can and will occur with degree and quality of processing. Current methods used by industry to evaluate soyabean quality are not capable of detecting differences between sources. Using a combination of quality criteria and not a single parameter appears the most appropriate when interpreting data.

References available on request from the author.