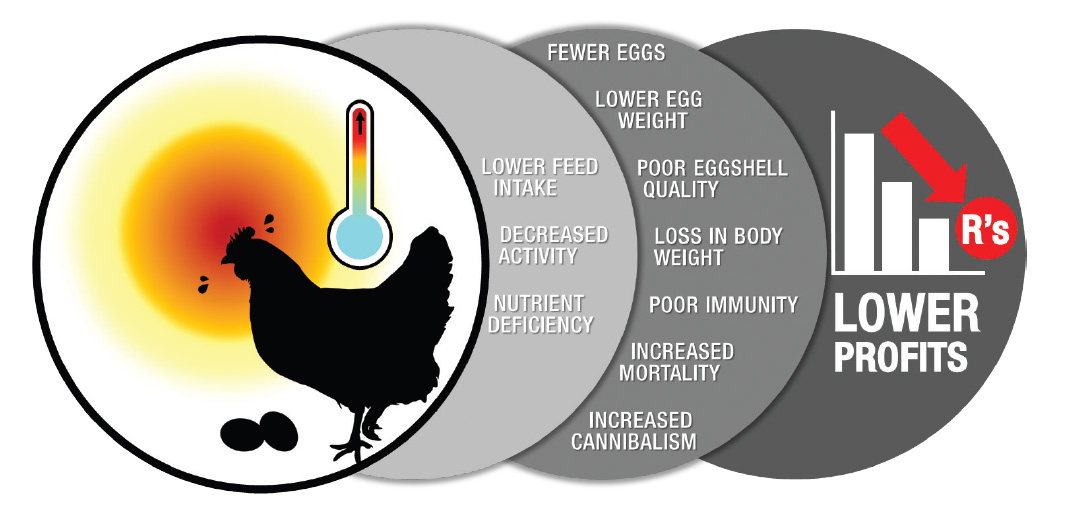

Moving into the summer months is often accompanied by periods of extreme heat and high humidity. Such environmental conditions can be detrimental to flock health and performance, with increases in mortality and decreased egg production and/or quality often evident.

Typically, a hen’s thermoneutral zone is between 18 and 25 °C, and within this range, sensible heat loss (radiation, conduction and convection) is enough to maintain the hen’s body temperature of 41 °C. Heat stress is experienced by the hen when she cannot maintain her body temperature through sensible heat loss. The heat stress experienced varies, depending on how far out of her thermoneutral zone she is.

At temperatures above 25 °C, evaporation of water from the respiratory tract becomes the main source of cooling for the hen and as the temperature increases further, they will begin to pant.

reduced calcium and carbonate secretion by the shell gland and consequently, the eggs will have thin, weak shells. This is an expensive process for both the farmer and the hen, as it is energy-expensive and will result in decreased production as well as a decrease in sellable eggs.

Typical effects of heat stress are summarised below:

• Decreased egg production and quality

• Decreased shell quality

• Loss in body weight

• Increased mortality

• Increased cannibalism

The management of heat-stressed flocks is crucial to ensure minimal losses. Common management practices to reduce the effects of heat stress include careful management of drinker systems, ventilation and cooling systems, and lighting and feeding programmes.

As with all livestock, water is the most essential nutrient for maintenance and production. Laying hens will usually consume twice as much water as they do feed, but this can increase to as much as eight times higher in periods of extreme temperatures. As such, the management of drinker lines is the first step to minimising the effects of heat stress.

Ensuring that water is readily available is the first step to mitigating heat stress. Adequate space and flow rate (70 ml/ minute/nipple) is essential for drinker lines and in the case of drinkers, space is the most limiting factor. Additional drinkers may be necessary to accommodate the extra water requirements.

Flushing of water lines or replenishing of drinkers will also help to improve water intakes, as water below 25 °C will result in higher intakes and also aid in cooling the hens’ core body temperature. Some water additives, such as vitamin C, can also help to reduce the negative effects of heat stress.

The next step is to ensure adequate ventilation and cooling. Air movement in the house will help cool the birds and as such, a minimum air velocity of 1.8-2.0 metres per second should be targeted. Stir fans are a good way to increase air speed in open- sided houses. Foggers and misters can also help bring house temperatures down, as well as sprinklers on the roof to cool the inside of the roof.

Changes to lighting and feed programmes are an effective method of reducing production losses. Reducing light intensity during the hottest periods of the day will reduce bird activity and subsequently, reduce heat generation and energy expenditure.

Adjusting the feeding schedule to offer feed in the coolest parts of the day is the best way to ensure adequate intakes. The early hours of the morning and evening are usually the coolest and as such, will be the most optimal time to improve feed intake. Midnight feeding, for roughly two hours, is also recommended to improve feed intake.

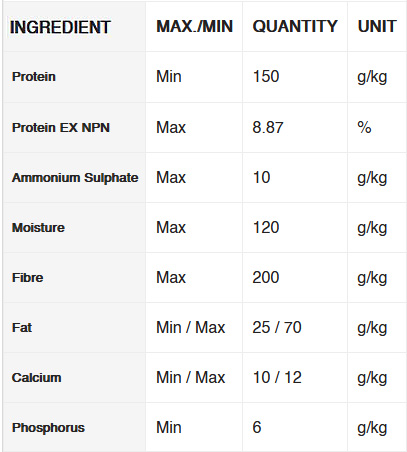

Other nutritional solutions include moving to a more nutrient-dense diet, the use of easily digestible raw materials, such as oil rather than starch (reduced heat increment), and the inclusion of additional raw materials, such as sodium bicarbonate, vitamin C and organic trace minerals, that can aid in minimising the negative effects of heat stress.

Heat stress can result in many physiological and physical effects in poultry, including reduced health and performance. The key to minimising these effects is predicting when these periods are likely to occur and making the appropriate management and nutritional changes to reduce the possible negative impacts.

Kyle Westergaard

Technical Manager at Epol, Rustenburg